WHAT IS SCOTCH YOKE PNEUMATIC ACTUATOR?

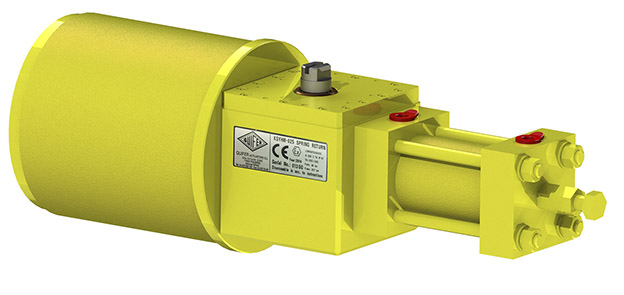

The Scotch Yoke pneumatic actuator is a stroke piston-type actuator, which is suitable for the on-off or metering control of the valve with a 90°rotation angle, like ball valve, butterfly valve, etc. By filling compressed air into the cylinder, the piston is pushed to move linearly. The piston uses the piston pin and the U-shaped groove design of the shift fork to convert the linear motion of the piston into the rotary motion of the shift fork. The rotation of the shift fork drives the output shaft to rotate, thereby realizing the valve control.

According to the different types of action, it can be divided into single-acting fork-type pneumatic actuators and double-acting fork-type pneumatic actuators.

SCOTCH YOKE PNEUMATIC WORKING PRINCIPLE

A scotch Yoke pneumatic actuator typically consists of a crank and piston system in a hollow cylinder. Pressure is applied to a side of the piston inside the cylinder. As a result, force is generated which moves the piston along the axis of the cylinder to rotate the actuator stem 90° with pilot air application. When the pressure is relieved, the piston then returns to its original position by a spring.

TYPES OF SCOTCH YOKE PNEUMATIC ACTUATOR

Double acting actuators

In a double acting actuator, air is supplied to chambers on both sides of the piston. Higher air pressure on one side drives the piston to the other side.

These types of actuation is used when actuation needs to be performed in both directions.

An advantage of double acting is the optimal output force through a full rotation range. The disadvantage is the need for compressed air for movement in both directions and a lack of defined position in case of power or pressure failure (fail last position).

Single acting actuators

In a single acting actuator, air is supplied to one side of the piston and is responsible for the movement of the piston in only one direction. The movement in the opposite direction is performed by a mechanical spring. Single acting actuators conserve compressed air, but perform in only one direction, but the spring brings the actuator in a defined position (e.g. safe position of the valve, fail safe close or open) by the spring. A disadvantage is the inconsistent output force through the full stroke due to the opposing spring force.

WHAT VALVE TYPES DOES A SCOTCH YOKE PNEUMATIC ACTUATOR WORK WITH ?

A scotch-yoke actuator is only suitable with 90˚rotation valves like butterfly and ball valves and ideal for variable torque valves.

OPERATION OF A VALVE REQUIRES A CERTAIN AMOUNT OF TORQUE

The operating torque of a valve is not constant along the stroke. A valve usually requires a higher torque on the start and the end of its stroke.

For a butterfly valve to start opening from a completely closed position, higher torque is required to overcome the friction between the seat and valve body. Lower torques are needed to keep the valve moving in the middle section of the valve stroke.

The torque output of a scotch-yoke actuator changes as a function of stroke position, resulting in higher torque at the beginning and end of the stroke.

ADVANTAGES OF SCOTCH YOKE PNEUMATIC ACTUATOR

- Large output torque

- Easy to install and easy to maintain

- Good explosion-proof performance

- To help you control remotely

APPLICATIONS OF SCOTCH YOKE PNEUMATIC ACTUATOR

When the torque requirement is higher than 7000Nm, rack-and-pinion actuators are often not cost-effective. For this reason, when selecting pneumatic actuators, it is generally recommended to choose high-power scotch yoke pneumatic actuators, which can provide higher torque output.

Scotch yoke type pneumatic actuators are suitable for major heavy industries, such as:

- Petroleum and natural gas

- Shipbuilding industry

- Paper and pulp industry

- Energy industry

- Power generation industry

- Mining